The improper configuration of screw compressor is extremely harmful ! What kind of cold storage project is more suitable for purchasing ?

Improving energy efficiency and making customers more flexible are always the purpose of Bitzer’ s product development and innovation. It is understood that Bitzer' s half screw models are complete, from 20 to 320, and the span is large. To the industry ' s surprise, the large number of 95 series screw compressor variable content product ratio, the same model can be applied to various working conditions from high temperature to low temperature. For example, the HS95 medium-low temperature screw product launched by Bitzer in 2021 can reach 280 KW refrigeration capacity under the operating conditions of low temperature conditions and economizer, and its exhaust volume at 50 Hz can reach 1015 m3/h ; the screw machine adopts pressure ratio adjustment technology, which is suitable for variable working conditions. Its general advantages of multi-clock refrigerants provide a guarantee for larger commercial and industrial refrigeration markets. If Party A chooses the Bitzer compressor for low temperature storage, the later business will change. In order to change into a high temperature storage, the equipment does not need to be changed. The system can also make the compressor operate under the optimal working condition according to the collected data.

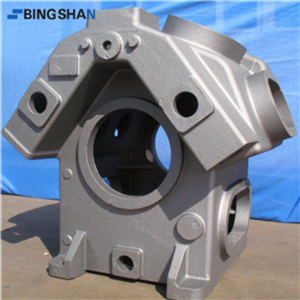

Bingshan launched a new concept in 2022 - ' Enter the new era of cold storage energy saving '. The compressor energy efficiency is the ceiling of system energy efficiency. Under the same reasonable system design, the higher the compressor energy efficiency is, the higher the system energy efficiency will be. Through single-machine two-stage technology, wide temperature range two-stage compression technology and frequency conversion technology, Bingshan comprehensively improves the energy efficiency of equipment in low-temperature application scenarios such as low-temperature refrigerated storage, quick-frozen storage and quick-frozen tunnel. The energy efficiency increases by more than 20 %, which can further significantly reduce the operation cost of equipment under the energy efficiency ceiling of the existing system.

Bingshan launched a new concept in 2022 - ' Enter the new era of cold storage energy saving '. The compressor energy efficiency is the ceiling of system energy efficiency. Under the same reasonable system design, the higher the compressor energy efficiency is, the higher the system energy efficiency will be. Through single-machine two-stage technology, wide temperature range two-stage compression technology and frequency conversion technology, Bingshan comprehensively improves the energy efficiency of equipment in low-temperature application scenarios such as low-temperature refrigerated storage, quick-frozen storage and quick-frozen tunnel. The energy efficiency increases by more than 20 %, which can further significantly reduce the operation cost of equipment under the energy efficiency ceiling of the existing system.

In recent years, Bingshan is committed to several technologies on new products :

1. Single two-stage screw and vortex products, one stage configuration screw two stage configuration vortex design, for small cold storage applications, can improve the energy efficiency of small cold compressor.

2. Single double slide valve design, configuration of double slide valve variable Vi, applied to the needs of quick freezing temperature, can improve the compressor operating range of two Vi applications.

3. For high-voltage products, 6000-10kV direct drive can be used for high-voltage products. For compressors with large cooling capacity and displacement requirements in some areas, the recent high-voltage models are divided into self-contained external oil separator and external oil separator. The displacement ranges from 1227m ^ 3 / hr to 1959m ^ 3 / hr. 4. For environmental carbon reduction and water resources reuse, Bingshan develops vacuum distillation technology, which can recycle wastewater and contribute to energy conservation and environmental protection.

At present, the development of cold storage will continue to develop towards large cold storage. Bingshan develops large displacement double-stage and single-stage machines for low temperature market to cope with the changes in the market.

Under the consistent design concept and quality standards, Bingshanhao has made different technological innovations or improvements for the existing series. The CO2 series after technical upgrading not only improves energy efficiency, but also adds new models ; the modification of the new screw series for FVR has been completed in 2020, and successfully pushed to the market at the end of the year.