Cooling Tower

-

Hot

Closed Cooling Tower

1. The cooling performance of the closed cooling tower is strong.

Email Details

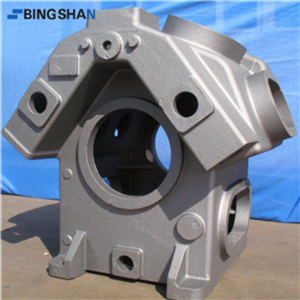

2. The coil of the closed cooling tower is connected by flanges, which is easy to disassemble and can improve work efficiency.

3. The closed cooling tower adopts unique parts processing, which is convenient for liquid outflow, easy for inspection and maintenance, and improves user experience. -

Hot

Square Cross Flow Cooling Tower

The FRP (glass fiber reinforced plastic) fan specially developed for the transverse flow cooling tower by spender manufacturing co., LTD. (with large rotation arc length, large intake surface, the noise during operation is concentrated on the tail of the blade, so as to minimize the noise generated by the transmission part).The three-dimensional filling material structure slows down the water flow speed. The water pressure of the inlet can be 0 through the natural gravity distribution of the perforated plate, and the water drops can flow directly into the water through the precise water level control of the inlet float valve, almost eliminating the water flow noise.

Email Details