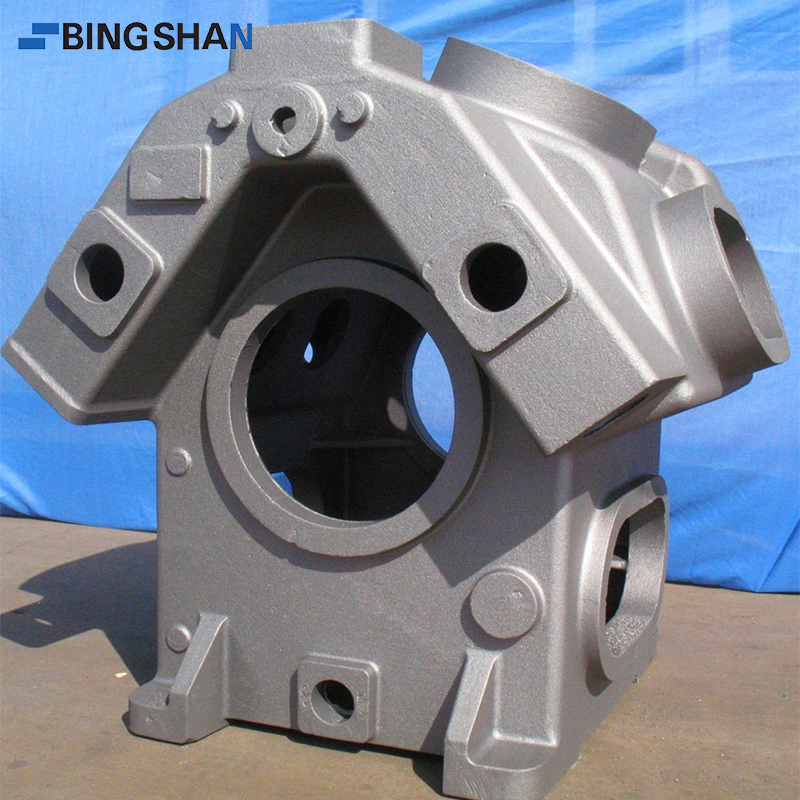

Iron Casting For Industrial Refrigeration

- Bingshan

- China

- 60-90days

- 12000 ton/year

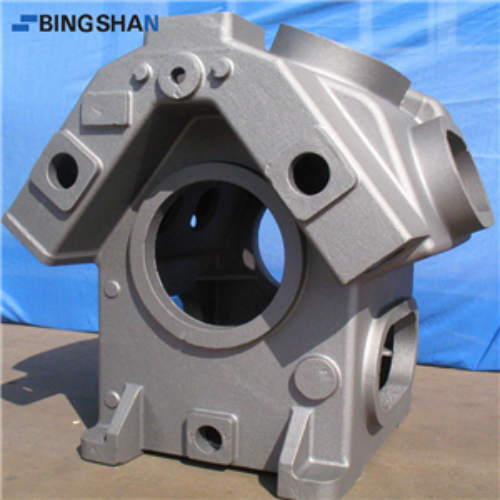

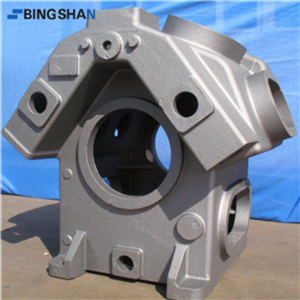

1. Industrial refrigeration cast iron parts can provide a variety of products such as gray iron castings, ductile iron castings, compressor body castings, shell castings, etc.

2. The surface of industrial refrigeration cast iron parts has been specially treated, which is corrosion-resistant and can extend the service life.

3. Industrial refrigeration cast iron parts have obtained ISO9000 quality system certification.

Introduction of Grey Iron Casting:

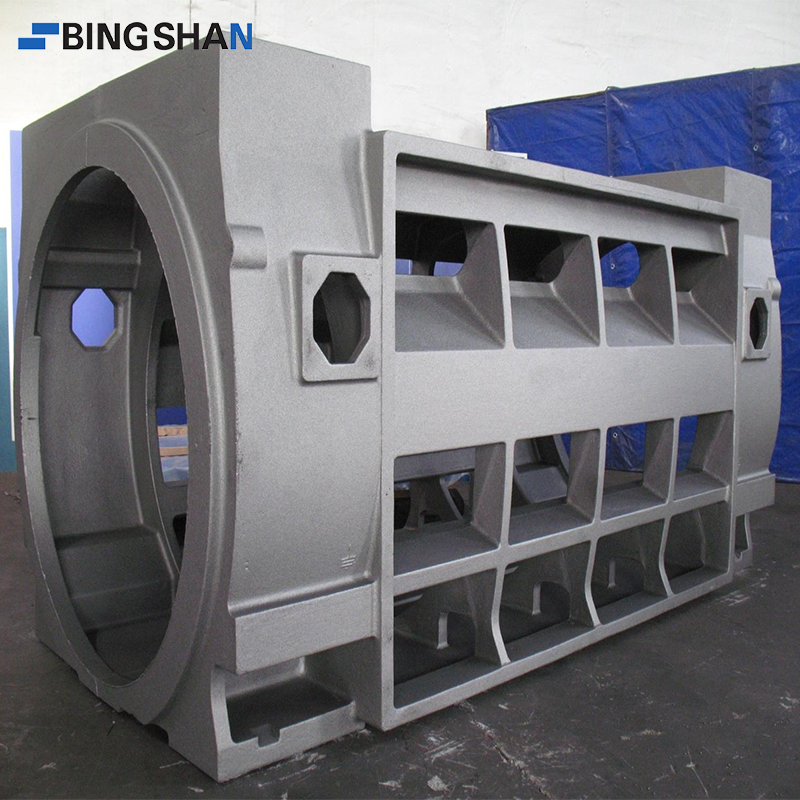

Grey iron casting is parts designed for industrial refrigeration systems. The cast iron material of grey iron casting has been cast and processed. Frame casting is corrosion-resistant and stable during use. These grey iron casting is widely used in refrigeration compressors, condensers, evaporators and other equipment.

Features of Grey Iron Casting:

1. Good Castability of Frame Casting:

The shrinkage of grey iron casting is small. Ductile iron casting can reduce the deformation. Frame casting cracks of castings. Industrial refrigeration cast iron parts have obtained ISO9000 quality system certification.

2. Ductile Iron Casting Can Reduce Shock:

Industrial refrigeration cast iron parts can absorb and disperse vibration energy. Frame casting is suitable for manufacturing parts that require good shock absorption performance.

3. Ductile Iron Casting is Wear-Resistant:

Housing casting contain hard matrix and soft graphite, so they are more wear-resistant. At the same time, graphite can also improve cutting processability. Frame casting reduce cutting resistance and tool wear.

4. Low Cost of Ductile Iron Casting:

The production process of gray cast iron for housing casting is relatively simple, and the source of frame casting materials is wide, so the cost is low.

Cast Iron Material Conditions of Housing Casting:

Housing casting use pig iron produced in Benxi, China. The sulfur and phosphorus content of housing casting is S< 0.03% and P< 0.06%. In addition, we also use steel with sulfur content: S< 0.3% and sand with silicon content of SiO2 ≥ 95%. Housing casting is furnace-melted and resin sand-molded. The product range of compressor casting is gray iron: HT200, HT250, HT300; ductile iron: QT400, QT450, QT500, QT600.

Application Areas of Compressor Casting:

Compressor casting is an important part of the refrigeration system, responsible for compressing and transporting refrigerants. Because compressor casting can withstand high pressure and high temperature while being wear-resistant. Therefore, compressor casting is often used to manufacture key components such as compressor cylinders and valve plates. In addition, frame casting can also be used to manufacture the shells and tube sheets of these equipment.

About Us:

The foundry is located at No. 106, Liaohe East Road, Jinzhou New District, Dalian City, with a total area of 40,000 square meters and a construction area of 21,352 square meters, including 15,988 square meters of production plants and 5,364 square meters of office buildings and other rooms.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more