Red Water Chiller with Ammonia System

- Bingshan

- China

- 60-90days

- 3000 set/year

1. The key components of the red water rechiller are easily accessible outside the equipment, and the removable U-bends facilitate full inspection and cleaning of all surfaces.

2. The red water rechiller is easily operated through HMI touch screen control. Monitor temperature and pressure, change control points, start antifreeze parameters and change evaporator pressure according to load requirements.

3. The red water rechiller uses food-grade stainless steel frames, jackets, process pipes, U-bends and tube sheets.

Introduction of Red Water Chiller with Ammonia System:

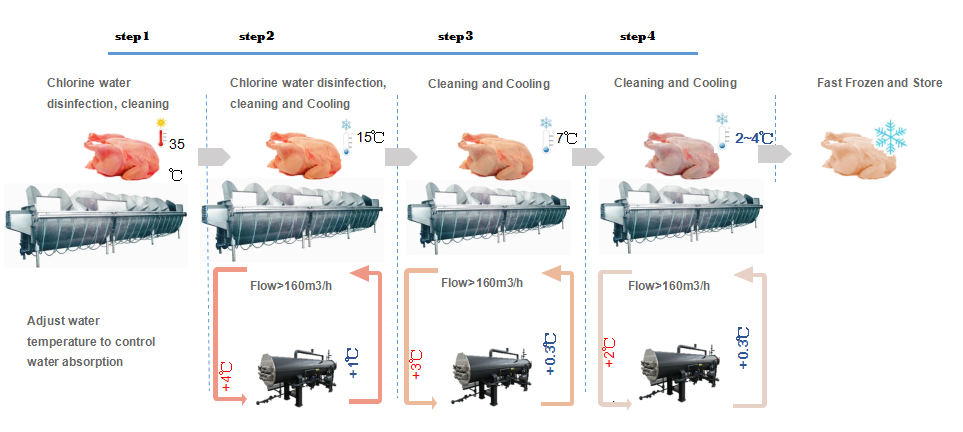

The red water chiller with ammonia system is mainly used for red water circulation cooling of carcasses produced in poultry slaughter lines or broiler slaughterhouses (2000-13500/hour). The red water chiller with ammonia system adopts spray liquid supply technology, falling film shell and tube heat exchanger structure design. Poultry chiller carefully selected control components. Poultry chiller rigorously set control procedures to provide stable. Poultry chiller reliable ice water at around 0.3~1℃.

Under the condition of ensuring reasonable chicken water and sufficient pre-cooling time, the poultry carcass can be cooled to below 4°C; at the same time, the low water temperature effectively inhibits the reproduction of microorganisms, the product quality after cooling is good, and the quick-freezing heat load is greatly reduced.

Red Water Chiller with Ammonia System Technical Processing:

Advantages of Poultry Chiller:

The temperature of poultry chiller before quick freezing is cooled from 20-10℃ to 4℃, and the heat load of poultry chiller is directly reduced to -7℃. The -25~-30℃ flake ice system of the has been upgraded to -7℃, with a total energy saving of more than 51%. The pre-cooling water cooling cycle of poultry chiller innovates the pre-cooling water cooling through flake ice to reduce water consumption. The poultry chiller adopts food machinery design, CIP automatic cleaning, and multiple cleaning technology. Chicken slaughterhouse is safe and reliable. The chicken slaughterhouse combined with the spiral pre-cooler. Chicken slaughterhouse can quickly reduce the core temperature of poultry meat to +4℃, meeting the requirements of freshness preservation. The chicken slaughterhouse can improve the quality of food, and the shelf life of refrigerated poultry products is doubled. The chicken slaughterhouse is relatively labor-saving. Chicken slaughterhouse has high cooling efficiency. Chicken abattoir is easy to operate.

Specification of Poultry Chiller:

Standard Products | Ref. Cap. (kw) | Water Flow (t/h) | L x W x H (m) | Net Weight (KG) |

HSMA300-Ⅱ | 300 | 160 | 5.1*1.6*2.1 | 3400 |

HSMA450-Ⅱ | 450 | 160 | 6.6*1.6*2.1 | 3900 |

HSMA600-Ⅱ | 600 | 180 | 8.1*1.6*2.2 | 4500 |

HSMA750-Ⅱ | 750 | 180 | 9.6*1.6*2.2 | 5200 |

HSMA900-Ⅱ | 900 | 230 | 6.6*2.0*2.7 | 7000 |

HSMA1200-Ⅱ | 1200 | 230 | 8.1*2.0*2.7 | 8400 |

Application Areas of Chicken Abattoir:

Chicken abattoir is often used to cool equipment such as injection molding machines and extruders. In the plastic processing process, chicken abattoir can maintain stable temperature. Chicken abattoir improve the quality of finished products. In the food processing industry, the cooling system of chicken abattoir is used in food processing, storage and transportation to extend the shelf life of food at a suitable temperature. In addition, laser equipment requires a stable cooling environment when working. Red water chillers can efficiently cool lasers to prevent the impact of high temperature on the equipment.

Project Photo:

Design And Structure of The Red Water Chiller:

The red water chiller adopts a combination of high-efficiency compressors, evaporators and condensers.Chicken abattoir can maintain the cooling efficiency. Stability of the red water chiller when the equipment is running. The water temperature can be reduced to the required temperature in a shorter time. In addition, the main components in the chiller adopt modular design. Chicken abattoir is convenient for disassembly, maintenance and replacement. And chicken abattoir reduces downtime.

Company Profile:

Dalian Bingshan Engineering & Trading Co., Ltd. is a professional trading company integrating consulting, design and sales. It has undertaken hundreds of turnkey projects in more than 60 countries and regions in Asia, Africa, America, etc., and provides customized energy optimization and sustainable cold chain solutions for them.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more