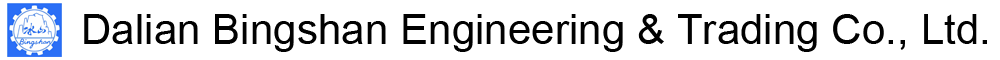

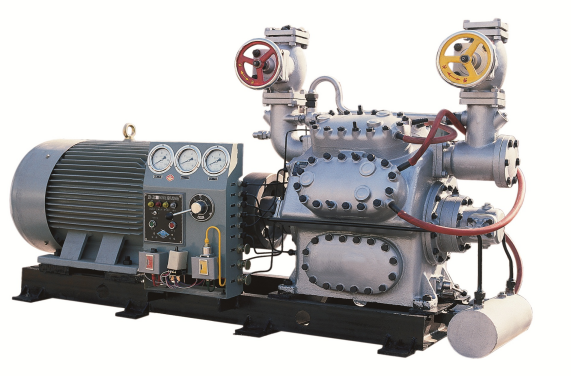

170 Series Reciprocating Compessor Unit

- Bingshan

- China

- 60-90days

- 3000 set/year

Product highlights:

1. The 170 series reciprocating compressor unit has a cooling capacity of 26.7 to 512 kW under standard working conditions of -15℃/30℃.

2. The 170 series reciprocating compressor unit is used in various fields that require artificial refrigeration, such as petroleum, chemical, pharmaceutical, and low-temperature laboratories for national defense research.

3. The 170 series reciprocating compressor unit uses Y series high-efficiency energy-saving motors with a protection level of IP23.

Features of Cold Room Compressor:

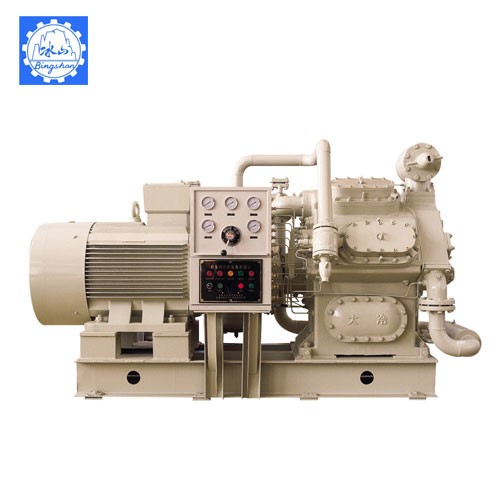

1. Cold Room Compressor is Energy Efficient:

Our cold room compressor uses Y series high-efficiency energy-saving motors with a protection level of IP23. Therefore, cold room compressor has a high unit speed, small size, and good component interchangeability.

2. Cold Room Compressor are Advanced in Equipment:

The compressor shaft seals and gaskets of cold room compressor are imported brands. In addition, our cold room compressor is also equipped with an energy regulation device. Ammonia reciprocating compessor can realize the unit's no-load start.

3. Refrigeration Reciprocating Compessorare Safe And Reliable:

Refrigeration reciprocating compessor is equipped with a three-way oil drain valve. Refrigeration reciprocating compessor can be filled with oil during normal operation. Ammonia reciprocating compessor Technology Parameter Table ensure safe operation.

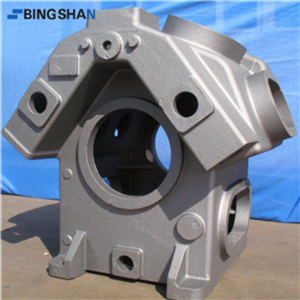

Details of Refrigeration Reciprocating Compessor:

The ammonia reciprocating compessor can reach a cooling capacity of 26.7 to 512kW under standard working conditions of -15℃/30℃. Therefore, ammonia reciprocating compessor is widely used in various fields that require artificial refrigeration. Not only is it used in low-temperature laboratories in petroleum, chemical, pharmaceutical, and national defense scientific research, our ammonia reciprocating compessor is also used in food low-temperature processing, storage and transportation, low-temperature testing, food low-temperature processing and storage, factories, hospitals and other large public places and buildings air conditioning.

Ammonia Reciprocating Compessor Technology Parameter Table:

Model Unit | JZY4AV17 | JZY6AW17 | JZY8AS17 | JZY4ASJ17 | JZY8ASJ17 | |||

Unit | Refrigeration Capacity | Standard Condition | KW | 256 | 384 | 512 | 81.4 | 163 |

Air Conditioning Condition | 558 | 840 | 1116 | |||||

Shaft Power | Standard Condition | KW | 71.9 | 107.1 | 142 | 42.75 | 83.9 | |

Air Conditioning Condition | 107 | 160 | 213 | |||||

Compressor | Theoretical Displacement | m3/h | 550 | 825 | 1100 | 137(412) | 275(825) | |

Capacity Regulating Range | 0,1/2,1 | 0,1/3,2/3,1 | 0,1/4,1/2,3/4,1 | 0,1/3,2/3,1 | 0,1/3,2/3,1 | |||

Suction Pipe Dia. | Mm | 100 | 125 | 150 | 65(100) | 80(125) | ||

Discharge Pipe Dia. | Mm | 80 | 100 | 125 | 65(80) | 65(100) | ||

Cooling Water Consumption | Kg/h | 2000 | 3000 | 4000 | 1500 | 2000 | ||

Note of Hermetic Compressor:

Conditions: Signle-stage: the maximum discharge pressure of reciprocating compressor ≤ 1.5MPa, the maximum discharge temperature of hermetic compressor ≤150℃, the maximum pressure ≤1.4MPa; two-stage: Low stage, the maximum discharge pressure of hermetic compressor ≤0.7Mpa, Maximum discharge temperature ≤120℃, the maximum pressure ≤0.8MPa; High stage, the maximum discharge pressure ≤1.5MPa, the maximum discharge temperature ≤150℃, the maximum pressure ≤1.4MPa.

· Data in parentheses are the low stage parameters.

· Standard condition: -15℃/30℃. Air conditioning: +5℃/+40℃

Workflow of Hermetic Compressor:

During the suction phase of hermetic compressor, the piston moves from the top dead center to the bottom dead center, a negative pressure is formed in the cylinder, and then the suction valve opens, and the low-pressure gas is sucked into the cylinder. During the compression phase, the piston of hermetic compressor moves from the bottom dead center to the top dead center, the cylinder volume decreases. Reciprocating compressor in turn causes the suction valve to close, the gas is compressed, and the pressure gradually increases. During the exhaust process, when the gas pressure in the cylinder of hermetic compressor reaches the set value, the exhaust valve opens, causing the high-pressure gas to be discharged from the cylinder. Reciprocating compressor enters the exhaust pipe or gas storage tank. When the piston of hermetic compressor moves from the top dead center to the bottom dead center again, the next working cycle begins.

Company Main Business:

Dalian Bingshan Group Co., Ltd. is a large mixed-ownership enterprise group, with industrial refrigeration and heating, commercial refrigeration and freezing and refrigeration, air conditioning and environment, core components, engineering and services, new business and other cold and hot businesses as the core.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more