Screw Compressor Unit (Dual-stage)

- Bingshan

- China

- 60-90days

- 3000 set/year

1.The refrigerants for the Screw Condensing Unit manufacturer include Ammonia (R717), Freon (R22, R134a, R744, R507A, R404A).

2.The refrigerating capacity range for the Dual-stage screw compressor unit is 148–2636 kW (-15°C/+30°C).

3.The Ammonia Screw Compressor produced by Iceberg is widely used in various industries requiring artificial refrigeration, including food storage and freezing, aquaculture, commercial, petroleum, chemicals, coal, textiles, pharmaceuticals, shipping, defense, and research.

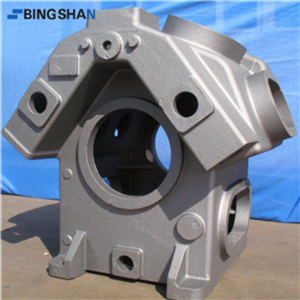

Screw Compressor Unit (Dual-stage):

1. The screw compressor unit adopts a sliding bearing design to reduce wear and extend service life. The equipment of screw compressor unit has fewer wear parts, runs smoothly. And screw compressor unit is suitable for long-term high-load operation.

2. The screw compressor unit features low discharge temperature and high volumetric efficiency. The screw compressor unit utilizes globally leading screw compressor rotor profile design to enhance compression efficiency and reduce energy loss.

3. The Ammonia Screw Compressor is equipped with stepless energy regulation. The Ammonia Screw Compressor automatically adjusting power according to load demand. The Ammonia Screw Compressor avoiding excessive energy consumption. And Ammonia Screw Compressor improving energy efficiency.

4. The Bitzer Semi-Hermetic Compressor supports manual control and microcomputer automatic control. The Bitzer Semi-Hermetic Compressor adapting to different operating needs and enhancing management flexibility.

5. The Bitzer Semi-Hermetic Compressor uses a microcomputer controller developed by the UK's Guardian Company. The Bitzer Semi-Hermetic Compressor offering fast response, precise control, and Bitzer Semi-Hermetic Compressor built-in fault diagnosis and safety protection functions.

6. The Commercial Refrigeration Compressor features a modular design.The Commercial Refrigeration Compressor making it easy to expand and maintain. The Commercial Refrigeration Compressor supports remote control and monitoring. The Commercial Refrigeration Compressor also enhancing operational convenience and management efficiency. The Commercial Refrigeration Compressor is widely used in daily life.

Parameter & Model | Unit | JZSLG16/12.5CS JZ2SLG16/12.5CS | JZFSLG16/12.5CS JZ2SLG16/12.5CS | JZSLG20/16SS JZ2SLG20/16SS | JZFSLG20/16SS JZ2FSLG20/16SS | JZSLG20/16MS JZ2SLG20/16MS | JZFSLG20/16S JZ2FSLG20/16MS | ||

| Double Stage Screw Compressor | Low Pressure Stage Discharge Capacity | M3/h | 624 | 821 | 1030 | ||||

High Pressure Stage Discharge Capacity | 197 | 416 | |||||||

Low Pressure Stage Discharge Capacity | 10%~100% Stepless Regulation | ||||||||

High Pressure Stage Discharge Capacity | 100% | 10%~100% Stepless Regulation | |||||||

| Main Motor | Electric source | 380V50HZ | |||||||

| Nominal Powver | KW | 100 | 140 | 150 | 160 | 175 | |||

| Compressor Unit | KW | 3 | |||||||

Bingshan JZLG Series Screw Compressor Unit Technology Parameter Table:

Unit Model JZLG | 12.5 | 12.5F | 16 | 16F | 20 | 20F | 25 | 25F | 31.5 | 31.5F | |||

Refrigerant | R717 | R22 | R717 | R22 | R717 | R22 | R717 | R22 | R717 | R22 | |||

Unit | Refrigeration Capacity | Air Conditioning Condition | KW | 307.1 | 278. | 650.5 | 591.2 | 1385.2 | 1258.9 | 2760.4 | 2508.4 | 5431.6 | 4935.8 |

Standard Condition | 148.1 | 147.9 | 315.7 | 314.3 | 672.3 | 669.3 | 1339.9 | 1333.7 | 2636.5 | 2624.4 | |||

Low Temperature Condition | 53.4 | 56.9 | 113.5 | 121.0 | 242.3 | 258.2 | 483.3 | 515.2 | 951.3 | 1014.0 | |||

Low Temperature Condition With Economizer | 63.8 | 75.3 | 135.7 | 159.7 | 289.4 | 340.2 | 577.3 | 677.0 | 1136.5 | 1339.4 | |||

Shaft Power | Air Conditioning Condition | KW | 55.3 | 52.7 | 116.5 | 111.0 | 245.2 | 233.5 | 487.7 | 464.4 | 959.1 | 913.2 | |

Standard Condition | 39.5 | 41.1 | 83.2 | 86.6 | 175.1 | 182.2 | 348.3 | 362.3 | 584.9 | 712.5 | |||

Low Temp. Condition | 34.8 | 36.9 | 73.1 | 77.6 | 153.5 | 163.1 | 305.6 | 324.6 | 601.0 | 638.4 | |||

Low Temperature Condition With Economizer | 35.5 | 39.5 | 74.6 | 83.0 | 156.5 | 174.1 | 308.8 | 343.3 | 606.1 | 675.2 | |||

Suction Pipe Diameter | mm | 100 | 100 | 150 | 200 | 300 | |||||||

Exhaust Pipe Diameter | mm | 65 | 80 | 100 | 150 | 200 | |||||||

Outline (LxWxH) | mm | 2770x1200x1850 | 2965x1355x1920 | 3610x1520x2280 | 4855x1975x3070 | 5930x2300x3350 | |||||||

Weight (About) | Air Conditioning Condition | Kg | 2240 | 2860 | 5850 | 11000 | 17200 | ||||||

Standard Condition | 2920 | 5690 | 10900 | 16600 | |||||||||

Low Temperature Condition | 5620 | ||||||||||||

Compressor | Theory Gas Transmission Rate | M3/h | 276 | 580 | 1215 | 2395 | 4700 | ||||||

Energy Adjustment Scope | % | 10~100 Stepless Adjustment | |||||||||||

Note of Double Stage Screw Compressor:

· Condition: Evap. Temp.:-40℃~ +5℃, Cond. Temp. ≤+43℃,Exhaust temp.≤+105℃.

Oil injection temp.: +25℃~ +65℃, Oil pressure higher than discharge pressure: -0.15~0.3MPa.

· Air Conditioning condition: +5℃/+40℃, Standard conditions: -15℃/+30℃, Low temperature condition: -35℃/+35℃

About Us:

Dalian Bingshan Engineering & Trading Co., Ltd. (Hereafter referred to as BSET) is jointly funded professional trading company by Dalian Bingshan Group Co., Ltd and Dalian Refrigeration Co., Ltd. in 1988. Concentrating on consulting, design, sales.

BSET provides Double Stage Screw Compressor to different application fifields including fruit and vegetable, meat and poultry, seafood, beverage etc processing and freezing & refrigerating fifield etc.

BSET has undertaken hundreds of turnkey projects in Asia, Africa, America etc. more than 60 countries and regions, as well as offer customized energy optimization and sustainable cold chain solutions.

Main Application:

The screw compressor unit is widely used in areas such as heating, ventilation, and air conditioning (HVAC), industrial refrigeration, food storage, trade and services, as well as original equipment and spare parts. In heating and ventilation systems, the Ammonia Screw Compressor provides stable temperature control and Ammonia Screw Compressor also provides air quality. In industrial refrigeration, the Ammonia Screw Compressor ensures efficient operation of the equipment and maintains an appropriate working temperature. In the food storage sector, the Bitzer Semi-Hermetic Compressor ensures food safety and freshness. The Double Stage Screw Compressor also supports equipment sales and technical support, and maintenance services in the trade and services industry. And Double Stage Screw Compressor offering original spare parts to extend equipment life. Double Stage Screw Compressor also ensure long-term stable performance.

Q1.What is our main product ?

A1: Our company mainly produces screw compressor unit,Ammonia Screw Compressor,Bitzer Semi-Hermetic Compressor,Commercial Refrigeration Compressor and Double Stage Screw Compressor.

Q2.When can I get the price ?

A2:We usually offer the quotation within 2-3 work days for equipment and 5-10 work days for system after receiving your inquiry. For urgent offer, please contact with us for special.

Q3.What is the Trade Term?

A3: We accept Ex-work factory , FOB Dalian, CNF or CIF, as your requirement.

Q4.How long is our Production leading time?

A4: It depends on type of equipment.

For cold storage equipment, the lead time is 60-80days after receiving down payment or Letter of credit.

For Double Stage Screw Compressor, the lead time is 80-90days after receiving down payment or Letter of credit.

For flake ice making unit and plate freezer, the lead time is 45days after receiving down payment or letter of credit.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more