Onion Cold Storage

- Bingshan

- China

- 60-90days

- 3000 set/year

1. The noise of the compressor unit for onion cold storage is low and the pollution to the environment is small.

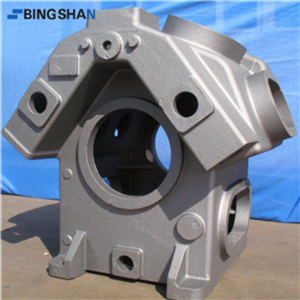

2. The compressor unit for onion cold storage can provide iceberg screw compressor, fan, air duct, evaporative cooling, low cycle barrel, high temperature cold storage.

3. The key components of the compressor unit for onion cold storage have been specially treated to be corrosion-resistant, which can extend the service life of the compressor unit for onion cold storage.

Introduction of Cold Storage Turnkey Project:

The cold storage turnkey project unit is the core equipment in the cold storage system. Cold storage turnkey project adopts advanced compression technology and intelligent control system. Cold storage turnkey project can operate stably in low temperature environment. The performance and selection of the cold storage turnkey project are directly related to the refrigeration effect and operation efficiency of the cold storage. There are many types of cold storage turnkey projects, each with its own characteristics. Choosing a suitable cold storage turnkey project can ensure the normal operation of the cold storage.

Working Principle of Cold Room Turnkey Project:

The cold room turnkey project is the most common type of refrigeration unit in the cold storage. The cold room turnkey project is mainly composed of a compressor, a condenser, an evaporator, a throttling device and other parts. The refrigerant of cold room turnkey project is compressed into a high-temperature and high-pressure gas by the compressor.cold room turnkey project becomes a liquid after the condenser dissipates heat, and then the pressure is reduced by the throttling device, and enters the evaporator to absorb heat to realize the refrigeration cycle. The cold room turnkey project has a large cooling capacity, high efficiency and good stability. Cold room turnkey project is suitable for cold storages of various sizes.

Key Points of Selecting Ammonia Refrigeration Solution:

1. Choose The Appropriate Type of Refrigeration Unit According to The Scale of The Cold Storage And The Items Stored:

For large ammonia refrigeration solution, you can choose a compression refrigeration unit; for small ammonia refrigeration solution or special occasions, you can choose an absorption or steam injection refrigeration unit.

2. According to The temperature of Ammonia Refrigeration Solution:

Different items have different temperature requirements, and you need to choose ammonia refrigeration solution. Ammonia refrigeration solution can meet the temperature requirements.

3. Consider The Energy Efficiency Ratio And Energy-saving Performance of The Ice Cream Processing:

Ice cream processing with high energy efficiency ratios can reduce operating costs and improve economic benefits; refrigeration units with good energy-saving performance can reduce energy consumption and emissions, and meet environmental protection requirements.

4. Pay Attention to The Noise and Vibration Problems of Ice Cream Processing:

The refrigeration unit will generate noise and vibration during operation. You need to choose a refrigeration unit with low noise and small vibration to ensure the quietness and comfort of the cold storage.

5. Consider The Reliability and Maintenance Convenience of Ice Cream Processing:

Ice cream processing with high reliability can reduce failure rates and maintenance costs; ice cream processing with convenient maintenance can reduce maintenance difficulty and costs.

Maintenance And Maintenance of Ice Cream Processing for Cold Storage:

1. Regularly Check The Operating Status of The Ice Cream Processing:

Regularly check the operating parameters of dairy processing, such as pressure, temperature, current, etc., to see ice cream processing they are within the normal range. Record the detailed data of each inspection to facilitate the discovery of abnormal trends of the compressor units for cold storage and deal with them in time.

2. Clean And Dust Dairy Processing:

Regularly clean the dairy processing for cold storage to remove dust and debris accumulation. Also check the internal components of dairy processing, such as the condenser and evaporator, to remove dust and dirt to ensure heat exchange efficiency.

3. Lubrication And tightening:

We need to add lubricating oil to the moving parts (such as bearings, pistons, etc.) regularly according to the requirements of the equipment manual to reduce wear between parts. In addition, we also need to check and tighten all bolts and connectors to prevent loosening or leakage.

4. Check The Refrigerant And Oil Level of Dairy Processing:

We need to check the refrigerant charge to ensure that it is within the specified range to avoid excessive or insufficient refrigerant affecting performance.

5. Regularly Replace The Wearing Parts of Dairy Processing:

Check whether the air filter, oil filter and other wearing parts are dusty or damaged, and clean and replace dairy processing in time.

6. Pay Attention to The Seasonal Maintenance of Dairy Processing:

In the high temperature season, focus on checking the cooling system of dairy processing and heat dissipation components of dairy processing to ensure that the equipment is not overheated. In the low temperature season, check the antifreeze measures to ensure that dairy processing can operate normally in a low temperature environment.

About Us:

Our excellent professionals focus on providing one-stop solutions for customers and pay attention to environmental protection services and the interests of customers. First-class brand products are the source of endless innovation. Dalian Bingshan is committed to creating a comfortable and clean living environment for mankind.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more