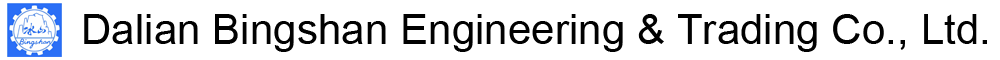

Slaughtering Plant Refrigeration Solution

- Bingshan

- China

- 60-90days

- 3000 set/year

1. The temperature of the slaughterhouse refrigerator in the acid discharge room is 0~4℃, which can ensure the quality of food.

2. The slaughterhouse refrigerator focuses on safety and hygiene in design and material use.

3. The temperature of the slaughterhouse refrigerator in the frozen food refrigeration workshop is -18~25℃, which can be flexibly controlled.

Introduction of Fruit Vegetable Processing:

The fruit vegetable processing is a refrigeration equipment designed for the slaughtering industry. Fruit vegetable processing can quickly cool. Fruit vegetable processing freeze meat products to ensure the freshness and quality of ingredients. The fruit vegetable processing can reduce the temperature of meat to a safe storage range in a short time. Ice manufacturing plant is widely used in slaughterhouses, meat processing plants and cold chain logistics centers.

Features of Fruit Vegetable Processing:

1. Fast Cooling Speed of Ice Manufacturing Plant:

The ammonia ice plant can quickly reduce the temperature of the animal carcass to a suitable storage level. Ammonia ice plant reduce the chance of bacterial growth, and ensure food safety.

Chicken Slaughtering focuses on hygiene in design and material use.

2. The Refrigerator Implements Zoned Temperature Control:

The refrigeration system of the ice manufacturing plant can control the temperature of different areas, such as the pre-cooling area, the cutting area, the packaging area, etc. The temperature of the ice manufacturing plant room can be controlled at 8~12℃ to keep the food fresh.

3. Environmental Protection of Ice Manufacturing Plant:

Our refrigerator adopts a low-energy consumption design.Chicken slaughtering selects a low-carbon emission refrigerant type. Ice manufacturing plant is green and environmentally friendly.

Working Requirements of Ice Cube Plant:

According to the process requirements of ice cube plant, carcasses and edible by-products that need to be pre-cooled after slaughter should be pre-cooled immediately in the ice cube plant. After cooling, the core temperature of livestock meat should be kept below 7℃, the core temperature of poultry meat should be kept below 4℃, and the core temperature of visceral products should be kept below 3℃. Processing, cutting, deboning and other operations should be completed as quickly as possible. When producing frozen products, the core temperature of meat should be lower than -15℃ within 48 hours before entering the cold storage.

Workflow of Ice Cube Plant:

Ice cube plant usually use compression refrigeration systems. The specific steps are as follows:

1. Evaporation Process of Ice Cube Plant:

In the condenser of the ice cube plant, refrigerants such as ammonia or Freon absorb heat from the surrounding environment. Chicken slaughtering change from liquid to gas.

2. Compression Process of Ice Cube Plant:

The gaseous refrigerant of chicken slaughtering is sent to the compressor for pressurization to increase its temperature.

3. Condensation Process of Ice Cube Plant:

The refrigerant in the chicken slaughtering enters the cooling tower or water cooling equipment. Chicken slaughtering releases heat and turns back into liquid.

4. Throttling And Pressure Reduction of Ice Cube Plant:

The liquefied refrigerant passes through the expansion valve to reduce the pressure, absorbs a large amount of heat instantly, and turns into a low-temperature and low-pressure gas state again.

This cycle is carried out continuously, ensuring the constant low temperature environment required during the chicken slaughtering, thereby effectively controlling the freshness and quality of the meat.

Reasons of Using Ammonia in Ammonia Ice Plant:

Ammonia ice plant has a certain bactericidal effect, so some slaughterhouses use ammonia ice plant for sterilization and disinfection. In addition, ammonia ice plant can reduce the temperature of the slaughterhouse. The temperature in the ammonia ice plant is generally high, and the ammonia gas can be passed in through the pipeline to prevent heatstroke and cool down. Especially when large cold storage uses liquid ammonia for refrigeration, the cost of ammonia ice plant will be relatively low.

About Us:

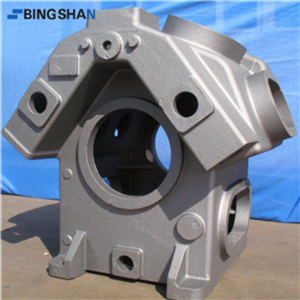

Bingshan Group is a large enterprise group with a new type of property rights relationship based on assets. It is my country's largest refrigeration and air-conditioning equipment manufacturing base, agricultural deep processing equipment base, and one of the main production bases of general machinery and equipment for petrochemical industry in my country.

We are the only door to overseas market for Dalian Refrigeration Co., Ltd. We have our own design team, installation team and after-sales team. We are professional engineering & trading company. We have set up branch office in Philippines, Malaysia, Thailand, Burma, Cambodia, Singapore, Bangladesh, Pakistan, Russian, Uzbekistan, Brazil, Argentina etc....more